Etnica Evolution

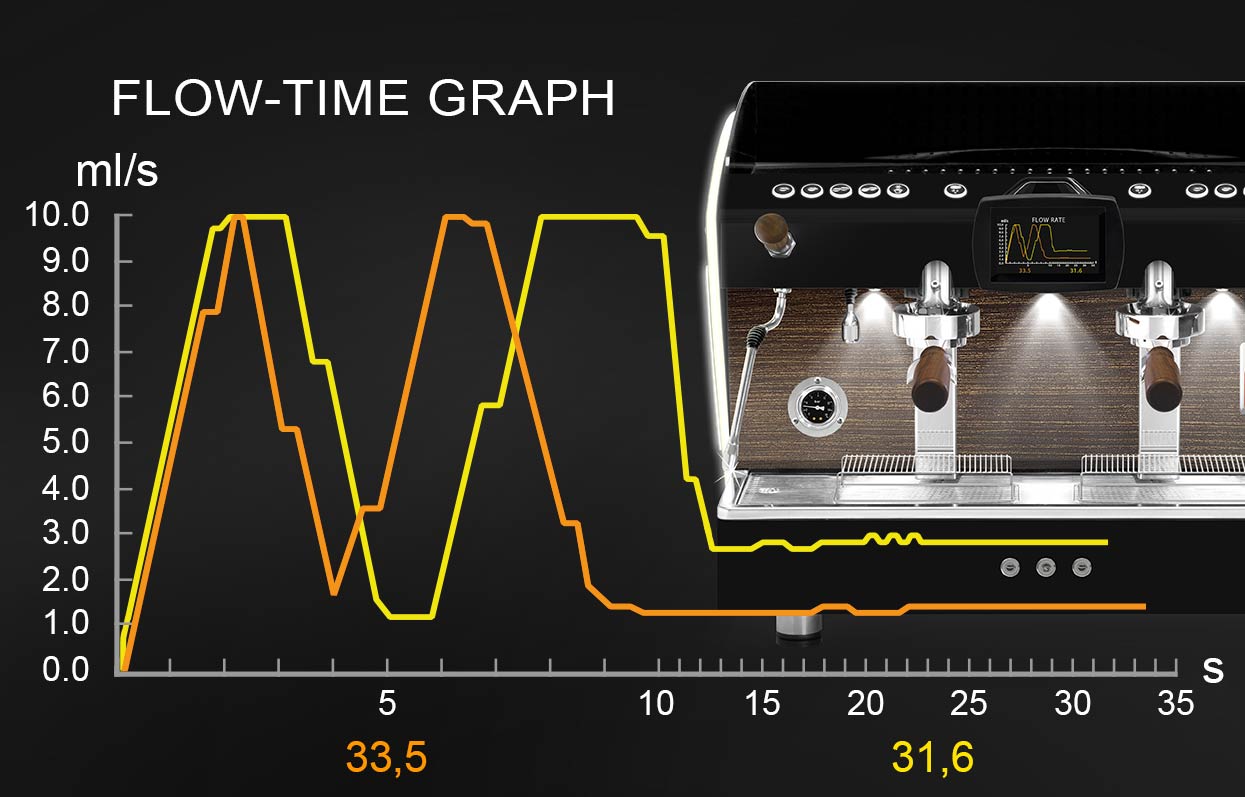

preinfusion and extraction Flow-Time graph

Very high control of preinfusion and dispensing, precision and reliability of temperature and pressure, energy saving and ease of maintenance.

High performance microcontrollers

With the use of high performance control and management microprocessors, both on the power board and on the display board, to manage, control and display coffee brewing parameters.

Displays of the dispensing status

Using the touch screen, the quantity of water and its time both in preinfusion and dispensing are displayed in real time.

For coffee roasters and professional baristas it is also possible to view a real time Flow-Time graph (FLOW RATE) that traces the profile of the preinfusion and dispensing flow of coffee spaced over time. These parameters are also displayed with simultaneous dispensing from each group.

Preinfusion and coffee dose programming

Programming of 4 preinfusion times for each independent E61 group: 8 preinfusions in the 2 group version and 12 in the 3 group version.

Programming of the total volume of doses for each independent brewing group.

The boiler pressure is controlled via a high-precision pressure transducer which allows adjustment of the boiler temperature via the display, with a greater adjustment range. To provide additional safety and continuity of work, the transducer is supported by an NTC probe which, in addition to detecting the temperature in the boiler, can also control it in the event of the pressure transducer not working. The precision and speed of repetition of the readings of the pressure values leads to a stability and reactivity of the thermal of the machine as the pressure of the boiler varies by a few hundredths of a bar which is equivalent to a very limited thermal oscillation of approximately 0,2°C compared to at 3,5°C of a machine with a traditional thermoregulation system with an electromechanical pressure switch in which during thermal maintenance, pressure variations of the order of 0.2 bar occur. With this pressure control, Etnica Evolution maximizes the thermal stability of the machine even during intensive use, significantly increasing its thermal capacity.

Energy saving

It is emphasised during all stand-by thanks to the independent electronic control of each one of 3 legs of the heating element, where the consumption drops to 1400 watt from a peak of 4200 watt.

Etnica Evolution is available with a copper boiler of greater thickness (standard boiler 12,5 lt diam. 205mm or optional flanged boiler 13 lt diam. 205mm.) equipped with a certified 10mm thick insulation for further energy saving.

Back up functions

2 semiautomatic buttons for coffee and 1 semiautomatic button for tea, manual refilling, NTC probe support.

Easier technical maintenance through:

- pull-out holder containing all the electrical and electronic controls of the machine so that it can be extracted for any intervention without having to remain near the machine and therefore without hindering the barista's work

- intuitive and tidy wiring by separating the low voltage part from the high voltage part with all named branches (cables)

- manual boiler water filling for manual use or in the event of any malfunctions due to external causes

- possibility of replacing the water inlet solenoid valve in the boiler by closing for the inlet and outlet taps of the solenoid valve and therefore without having to turn off the machine or turn off the water supply or empty the boiler

Accessory functions:

alarm alerts, the automatic on/off timer, the bar's day off, the language, turning the machine on/off, counter page, electric cup heater (with ON/OFF switch) with programmable working temperature, customizing the barista password, adjusting the sensitivity of the level probe based on the hardness of the water, programming and warning of maintenance cycles, filter replacement, boiler load synchronization, maximum boiler load time.

Optional: external motor pump (air cooling), cappuccino maker/milk frothing wand, serial interface for external connection to the cash register, white filter holders for 1 and 2 cups, nut wood kit (filter holders and knobs), color options and aesthetic customisation.

Very high control of preinfusion and dispensing, precision and reliability of temperature and pressure, energy saving and ease of maintenance.

High performance microcontrollers

With the use of high performance control and management microprocessors, both on the power board and on the display board, to manage, control and display coffee brewing parameters.

Displays of the dispensing status

Using the touch screen, the quantity of water and its time both in preinfusion and dispensing are displayed in real time.

For coffee roasters and professional baristas it is also possible to view a real time Flow-Time graph (FLOW RATE) that traces the profile of the preinfusion and dispensing flow of coffee spaced over time. These parameters are also displayed with simultaneous dispensing from each groups.

Preinfusion and coffee dose programming

Programming of 4 preinfusion times for each independent group: 8 preinfusions in the 2 group version and 12 in the 3 group version.

Programming of the total volume of doses for each independent brewing group.

The boiler pressure is controlled via a high-precision pressure transducer which allows adjustment of the boiler temperature via the display, with a greater adjustment range. To provide additional safety and continuity of work, the transducer is supported by an NTC probe which, in addition to detecting the temperature in the boiler, can also control it in the event of the pressure transducer not working. The precision and speed of repetition of the readings of the pressure values leads to a stability and reactivity of the thermal of the machine as the pressure of the boiler varies by a few hundredths of a bar which is equivalent to a very limited thermal oscillation of approximately 0,2°C compared to at 3,5°C of a machine with a traditional thermoregulation system with an electromechanical pressure switch in which during thermal maintenance, pressure variations of the order of 0.2 bar occur. With this pressure control, Etnica Evolution maximizes the thermal stability of the machine even during intensive use, significantly increasing its thermal capacity.

Energy saving

It is emphasised during all stand-by thanks to the independent electronic control of each one of 3 legs of the heating element, where the consumption drops to 1400 watt from a peak of 4200 watt.

Etnica Evolution is available with a copper boiler of greater thickness (standard boiler 12,5 lt diam. 205mm or optional flanged boiler 13 lt diam. 205mm.) equipped with a certified 10mm thick insulation for further energy saving.

Back up functions

2 semiautomatic buttons for coffee and 1 semiautomatic button for tea, manual refilling, NTC probe support.

Easier technical maintenance through:

- pull-out holder containing all the electrical and electronic controls of the machine so that it can be extracted for any intervention without having to remain near the machine and therefore without hindering the barista's work

- intuitive and tidy wiring by separating the low voltage part from the high voltage part with all named branches (cables)

- manual boiler water filling for manual use or in the event of any malfunctions due to external causes

- possibility of replacing the water inlet solenoid valve in the boiler by closing for the inlet and outlet taps of the solenoid valve and therefore without having to turn off the machine or turn off the water supply or empty the boiler

Accessory functions:

alarm alerts, the automatic on/off timer, the bar's day off, the language, turning the machine on/off, counter page, electric cup heater (with ON/OFF switch) with programmable working temperature, customizing the barista password, adjusting the sensitivity of the level probe based on the hardness of the water, programming and warning of maintenance cycles, filter replacement, boiler load synchronization, maximum boiler load time.

Optional: external motor pump (air cooling), cappuccino maker/milk frothing wand, serial interface for external connection to the cash register, white filter holders for 1 and 2 cups, nut wood kit (filter holders and knobs), color options and aesthetic customisation.